How to Choose the Right Pallet Wrapping Machine for Your Business

In today’s fast-paced industrial world, the efficiency of your packaging process can make or break your business’s ability to deliver products safely and on time.

Choosing the right pallet wrapping machine is a critical investment that can significantly enhance your operational efficiency, reduce labor costs, and ensure the secure delivery of goods.

However, with the range of machines available, understanding which option is best suited to your business’s specific needs can be overwhelming.

In this expert guide, we’ll walk you through the essential factors to consider when choosing the right pallet wrapping machine, offer advice on best practices, and provide insight into how the right machine can positively impact your bottom line.

Understanding the Different Types of Pallet Wrapping Machines

Before diving into which pallet wrapping machine is right for your business, it’s important to understand the basic types of machines available.

These machines generally fall into three categories, each designed to serve different business sizes and packaging volumes.

Manual Pallet Wrappers

Manual machines are ideal for small businesses or operations with low-volume packaging requirements. These require manual labor to operate, but they provide the flexibility of low-cost entry without the need for heavy investment.

Buy our hand wrap rolls at best price

- Hand Wrap Stretch roll: 500(w)x300(l)x12mu

- Hand Wrap Stretch roll: 500(w)x300(l)x17mu

- Hand Wrap Stretch roll: 500(w)x300(l)x20mu

- Hand Wrap Stretch roll: 500(w)x500(l)x23mu

Semi-Automatic Pallet Wrappers

For businesses with moderate packaging volumes, semi-automatic machines are a great choice. These machines handle most of the wrapping process, though an operator is still required to load and initiate the wrapping cycle.

This type balances cost-effectiveness and efficiency, providing solid performance while keeping operational complexity low.

Fully Automatic Pallet Wrappers

High-volume operations that require speed, consistency, and minimal manual intervention benefit most from fully automatic machines.

These are designed for large-scale operations where pallet loads are high, and consistent throughput is critical. Fully automatic machines can integrate with conveyor systems and reduce labor requirements drastically.

Expert Insight:

While smaller operations may lean toward manual or semi-automatic wrappers for their lower upfront cost, large businesses with high packaging volumes will see the greatest ROI with a fully automatic system due to increased throughput and reduced labor costs.

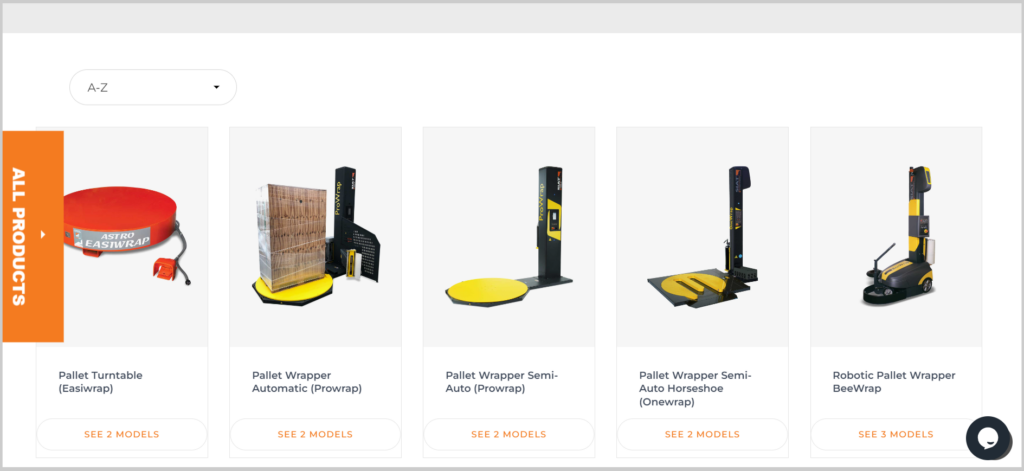

Find best selling products

As your business grows, so do your packaging needs, and investing in scalable technology can save you from constant machine upgrades.

Key Considerations When Choosing a Pallet Wrapping Machine

To ensure that your investment is tailored to your specific needs, here are several critical factors to consider:

Load Size and Shape

The size, weight, and shape of your pallet loads will largely determine the type of machine you need. If your loads are standard-sized and uniform, most machines will work.

However, irregularly shaped loads, or loads that are very light or heavy, may require a more advanced machine with customizable tension settings or pre-programmed cycles.

Packaging Volume and Frequency

How many pallets do you need to wrap in a day, week, or month? The frequency and volume of pallets directly impact the type of machine you should choose.

Lower-volume operations may find a manual or semi-automatic machine sufficient, while businesses wrapping hundreds of pallets per day will benefit from the speed and efficiency of a fully automatic system.

Film Type and Compatibility

Different machines work with various films, such as machine-grade pallet wrap, stretch film, or vented wrap. Understanding the type of wrap you use is essential in selecting the right machine. Some machines are optimized for certain film types, ensuring they stretch the film to the optimal tension without causing tears or damage to the load.

Key Tip:

For the most efficient operation, choose a machine that offers variable pre-stretch options, as this will help minimize film use while ensuring the load is secure. This can significantly reduce your material costs over time.

Read more

- The Packaging Company: Best for Cost-Effective Pallet Wrap Solutions

- The Origins of Pallet Wrapping: Our Journey Uncovered

Operational Efficiency and Automation Features

How important is speed to your operation? Businesses that need to move products quickly will benefit from machines with higher automation features, such as conveyor integration or multi-pallet wrapping capabilities. Machines with automated film cutting and load detection can further streamline operations, reducing the need for manual oversight.

Total Cost of Ownership (TCO)

While it’s tempting to focus solely on the initial cost of the machine, it’s crucial to consider the Total Cost of Ownership (TCO).

This includes not just the upfront price but ongoing costs such as energy consumption, film use, maintenance, and potential downtime.

Investing in a high-quality machine may seem expensive upfront, but lower running costs, reduced maintenance, and improved operational efficiency can save you money in the long run.

Safety and Ergonomics

The safety of your workers should always be a top priority. Ensure the machine you choose is equipped with safety features like emergency stop buttons, sensors to detect obstructions, and smooth, user-friendly controls. Semi-automated systems that reduce the need for manual labor can also help prevent repetitive strain injuries in workers.

Pallet Wrapping Machine Best Practices for Maximizing ROI

Now that you know how to choose the right machine, let’s discuss best practices for using your investment efficiently.

Regular Maintenance

Like any industrial equipment, your pallet wrapping machine needs regular maintenance to function at peak efficiency. Schedule regular inspections and cleanings, and ensure that the film rollers and moving parts are in good condition.

Optimize Film Usage

Proper pre-stretch settings on your machine can optimize film usage, reducing waste while ensuring the load is securely wrapped. Some machines offer variable pre-stretch settings, which can save up to 50% on film costs.

Train Operators

Ensure your operators are properly trained to use the machine. Efficient operation requires understanding settings, film tension, and wrap cycles. Misuse can lead to product damage or excessive film use, negating cost savings.

Monitor Load Variability

As your product mix changes, adjust the machine’s settings to accommodate new load sizes and shapes. Ensuring the right settings will reduce film waste and potential product damage during transit.

Recommended Pallet Wrapping Machines for Different Business Sizes

To make your decision easier, we’ve curated some recommendations based on business size and packaging needs:

- For Small Businesses (Low Volume):

The Semi-Automatic WrapMate 200 is an excellent choice for businesses wrapping 10-20 pallets per day. With easy-to-use controls and adjustable film tension, it balances affordability with essential features. - For Medium Businesses (Moderate Volume):

The AutoWrap Pro 500 offers automation for businesses with higher throughput. Its advanced pre-stretch system minimizes film use, and the touch-screen interface allows you to adjust wrap cycles and load sizes efficiently. - For Large Enterprises (High Volume):

The MaxWrap 1000 is designed for high-volume operations. Fully automated, it integrates with conveyor systems and can handle thousands of pallets per day with minimal manual intervention. Its precision sensors ensure each load is securely wrapped with minimal waste.

Final Thoughts: Investing in the Right Pallet Wrapping Solution

Selecting the right pallet wrapping machine isn’t just about improving your packaging efficiency—it’s about optimizing your entire supply chain. From reducing material costs and labor hours to improving the safety of your loads during transit, the right machine can offer a substantial return on investment.

Business owners who take the time to assess their needs carefully, consider future growth, and choose a machine that matches their volume and load variability will see the most significant benefits. Whether you’re just starting out with a semi-automatic machine or upgrading to a fully automated solution, making the right choice can transform your business operations.

Remember, investing in quality today will save you time, money, and headaches down the road. Choose wisely and partner with a reputable supplier to ensure long-term success in your packaging process.